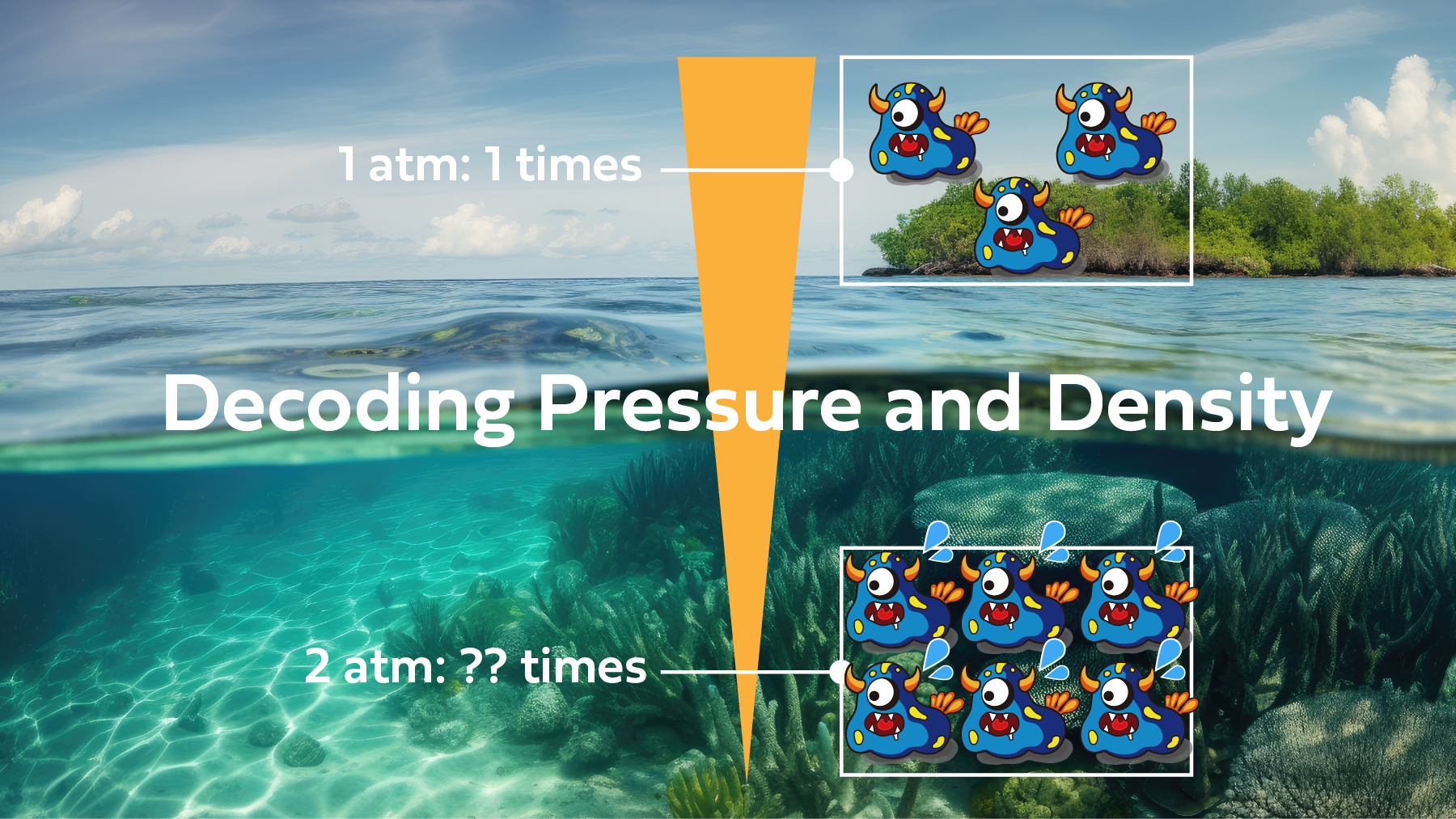

Sneaking into Japan’s No. 1 wetsuit factory!

Take an in-depth look at the manufacturing process of wetsuits

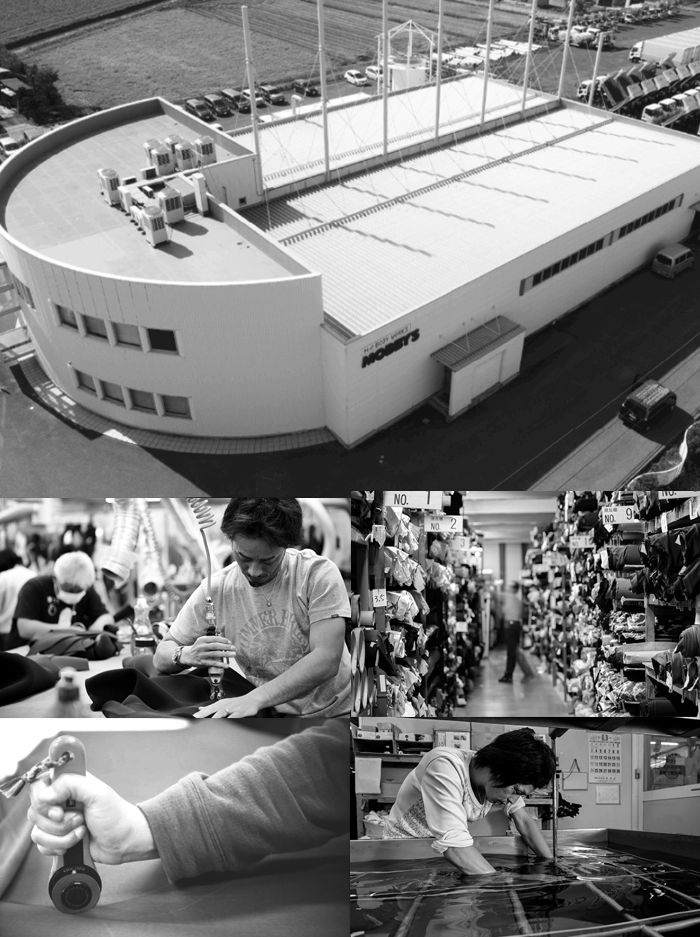

The full-order wetsuits and dry suits you order are manufactured at our head office and factory (MOBBY DICK INC.) in Ishinomaki City, Miyagi Prefecture. * Excluding some products, our head office and factory have produced more than one million wetsuits and dry suits since 1963. We started with custom-made wetsuits for local fishermen, and now we manufacture wetsuits for various marine sports such as surfing, scuba diving, personal watercraft, and yacht. Our customers are not limited to the fishing industry and leisure related industries, but we also provide wetsuits and dry suits for government offices in Japan and overseas.

Until the wet suit and dry suit are delivered to the customer

1.Model selection and measurements

Choose a model according to the area, season and your surfing style. Depending on the model, you can choose fabric colors, marks, and custom options*. Please use MOBBY’S color simulator and O’NEILL color simulator when choosing fabric colors and marks.

For custom orders, measurements are taken manually by the staff of the store that carries the product. More than 30 measurements are taken to ensure that the wetsuit or dry suit fits your body correctly.

Fill in all the necessary information in the order sheet and send it from the store to the factory by e-mail or fax.

Custom options vary by model. Please refer to the website or catalog for details.

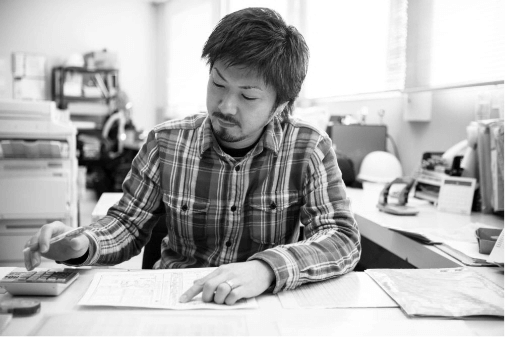

2.Order sheet acceptance process

When the customer’s order sheet arrives at the factory from the store, we check to see if there are any gaps.

3. Check the measurements

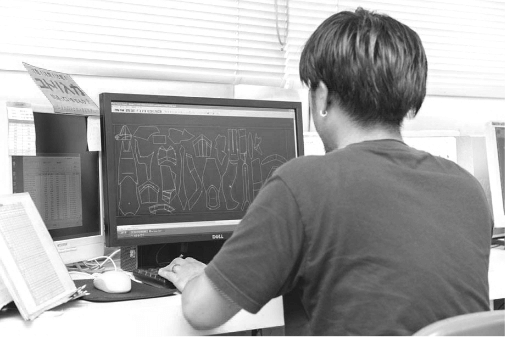

While checking about 30 measurements on the order sheet, input the measurements into the special software for pattern making. If necessary, our dedicated staff will make corrections to the values or contact the store.

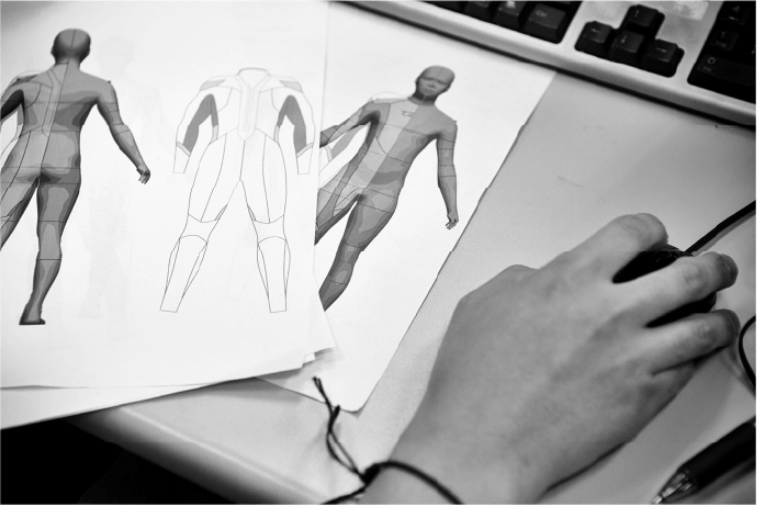

4. Output the pattern

When we input the measurements into the special software for pattern making, the pattern will be automatically output. A pattern consists of about 30 to 50 parts, depending on the model. The head office and factory have introduced the world’s first CAD system specifically for wetsuits. The output pattern is manually modified by a few millimeters, and then it goes on to the fabric cutting process.

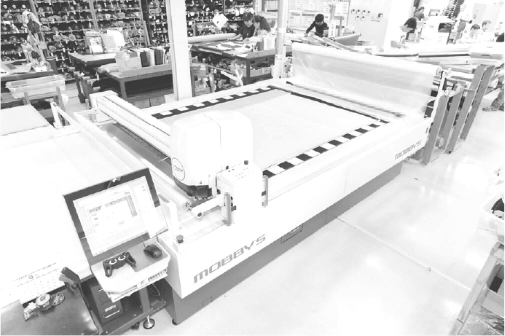

5.Cutting the fabric

Pick up the fabric to be used for the ordered suit from about 800 kinds of fabrics. The pattern is placed on the fabric, marked, and cut with a special cutter.

A special roll cutter is used to cut the fabric. The craftsmanship of moving the cutter all at once to avoid distortion of the fabric cross-section can only be done by skilled staff. Distortions or unevenness on the cutting surface will not only cause problems in adhesion and cutting, but may also lead to the suit being submerged in water.

In addition, automatic cutting machines have been installed at our head office and factory, which are used for the production of ready-made suits and other applications.

6.Gluing the fabric

Special adhesive is applied to the cross-section of chloroprene fabric, and the parts are then attached by hand. In addition to flat parts, skilled techniques are required to finish three-dimensional parts. The index finger of a veteran staff member has calluses and sometimes bends outward.

Special tool may be used to crimp the fabric sections together.

7.Sewing the fabric

There are 9 different types of sewing machines at our head office and factory, and we use them according to the type of fabric and application.

“Blind stitch” is an essential sewing method for wetsuits and dry suits and uses a special needle to sew a few millimeters of the surface without penetrating the fabric. It takes several years to learn to use a special sewing machine for the blind stitch.

After the suit is completed, it is inspected before shipping. There are about 30 items to be inspected, including every corner of the suit’s surface and back. After a visual inspection by our dedicated staff, only those suits that pass the inspection will be shipped.

9.Shipment

The suit will be covered with plastic cover to prevent stains and scratches, and packed in a special box. Final confirmation of the shipping slip and shipping address, and handover to the carrier.

When the suit arrives at customer’s home, remove it from the packing box as soon as possible and hang it in a well-ventilated place out of the sun for storage.

We would like to ask you to register as a customer so that we can improve our services. We appreciate your cooperation. For more information on wetsuit and dry suit maintenance, please click here.